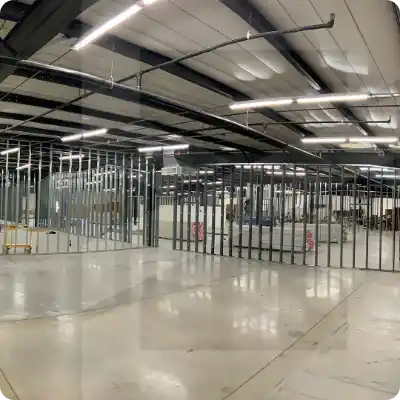

4. ASSEMBLY AND INSTALLATION

Once prepared, the metal frames are assembled on-site or off-site. Skilled workers bold, weld, or rivet the pieces together, creating a stable frame that forms the structural backbone of a bulding, trailer, or other structure.